CoBo-Stack Automatic Palletizer

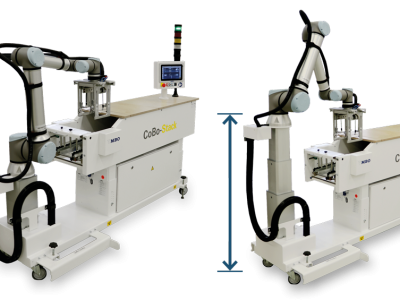

The MBO CoBo-Stack is a completely automatic collaborative robot needing no protective cage. Stacks of folded signatures, are transported from an automated delivery to a proper pattern on a pallet, reducing the physical demands of the operator. While the CoBo-Stack attends to the delivery, the operator has time to carry out other tasks such as quality control, feeder loading or preparing the next job. Now it is possible to have 1 operator running 2 machines in a true manufacturing cell. The CoBo-Stack truly fits the new print market demanding high productivity with minimal labor and set up time.

Highlights:

- Cobot design for safety so no protective cage is needed

- Eliminates labor on the back end of the folder

- Short makeready using a simple menu from a hand held tablet device

- Allows operation model of 2 machines with 1 operator in appropriate application

- Pallets can be placed on both sides of the CoBo-Stack allowing uninterrupted production

- Optical and acoustical signals show various operating statuses

- Can be used on any brand folding machine

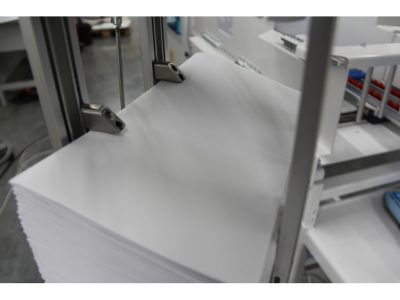

- Works in conjunction with Palamides alpha series stacking deliveries

- RAS Remote Access Router included

- Mobile design so it can be used on multiple machines in the facility

Recent Innovations:

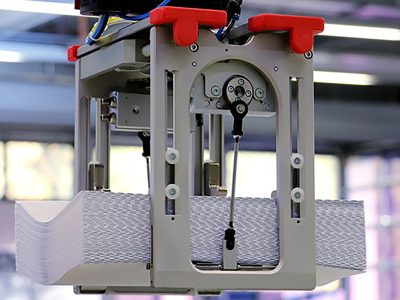

- Stacking height increase up to 140 cm (55“) achieved by a height-adjustable robot arm, reducing pallet quantity and saving time and money

- For A/B split, double stream production it is now possible to alternately stack both pallets at the same time

- New stacking pattern for 10 piles

- Stacking Continuance: To continue stacking on a pallet that has already been started, simply enter the actual height of the started pallet and go

- Deposits two signatures on one pallet

- XS gripper enables an even wider range of paper formats

- Increased stack weight to 17 5/8 Ib

U.S. Patent No. 10,968,056

Image Gallery

Technical Specifications

CoBo-Stack in detail

CoBo-Stack on MBO T800.1 Folder at Printing United 2019

MBO CoBo-Stack with Saddle Stitcher

MBO CoBo-Stack applied to Stahl folder or Third Party Folder

CoBo-Stack on Muller Martini Perfect Binder