K80 Combi Buckle/Knife Folding Machine

Overview:

The K80 is MBO’s new combi folding machine for full size B1 and smaller sheet sizes. With a blazing maximum machine speed, and wide range of fold pattern capabilities, it is well suited to the North American commercial print market and is ideal for high-precision, high-performance production of signatures, flyers and other general commercial products in industrial print environments. Bolstering a 230 meter/minute (9,055 inches/minute) running speed, a common 25″ x 38″ sheet can be processed up to 13,755 sheets/hour; and smaller sheets even faster! Even with conservative estimates, this represents a substantial increase in production rates over nearly any earlier vintage folding machine. Ease of operation plays an important role in today’s market and the K80 is built with the operator in mind. MBO’s latest M1 controls platform uses a simple graphical interface with intuitive menu choices and complete integration. Connectivity to the internet provides a way for MBO to gain remote access for service or software upgrades. The K80 also utilizes a host of exclusive MBO design features like the slitter-shaft cassette for faster tooling changes, high speed knife folders in the second and third position, and servo controlled combi-plates eliminating manual adjustment and deflectors. Easier processes, user friendly controls and automated functions, get jobs on and off the machine faster, translating to more uptime and maximum productivity. Even in today’s fast turn, short run market, the K80 is allowing today’s printer to think in terms of replacing vintage machines at a ratio of up to 2:1 or more while still reducing labor.

Highlights:

- Palletized feeder or continuous feeder for best fit to print environment and labor reduction plans

- 4 or 6 NIRO style non-corroding buckle plates in the parallel fold unit, first fold

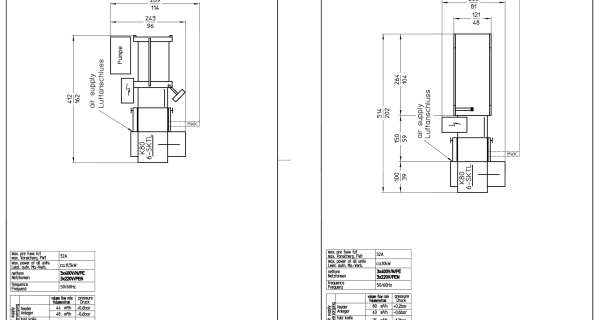

- SKTL or SKTL knife fold configurations for customized performance

- Manual or automated control system

- Enhanced 230 m/m (9,055 ipm) folder running speed

- Eliminates moving modules during makeready for shorter set up times

- Small footprint to conserve building space while adding to productivity

Standard Features and Benefits:

- MBO’s advanced M1 control system and graphic HMI for ease of use

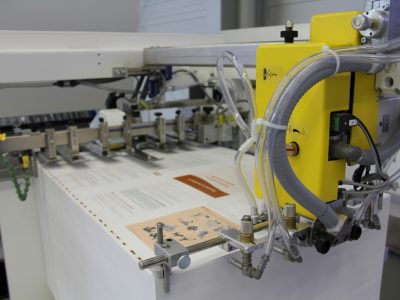

- Vivas (Double-Vacubelt and Vacutable) for constant sheet pull and best registration

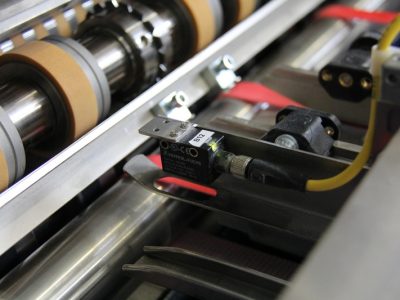

- Ultrasonic double sheet control in the feeder/ alignment table for additional machine security

- Anti-static lattice alignment table for consistent sheet control during registration

- MBO’s exclusive, low maintenance, silent belt drive for low cost of operation and high quality

- Virotec fold rollers for the ultimate paper grip at the lightest pressure possible

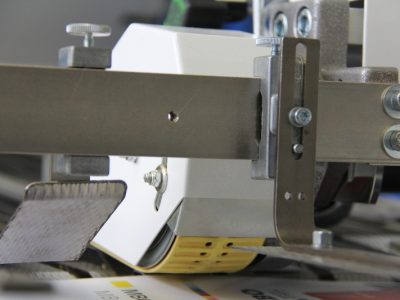

- Slitter shaft cassette in the parallel fold for fast makeready and kit style tooling changes

Optional Features and Benefits:

- Pre-slitter shaft at entrance to parallel fold buckle plates for additional tooling like scores and perfs

- Gatefold plate in the parallel unit for enhanced folding capability for two fold and three fold gates

- DATAMANAGER 4.0 connection to the K80 series M1 controls for data gathering and machine preset data

- Edge trim, center bleed trim, score tooling and perforation tooling

- The K80 series can interface to many automated deliveries, and even robots, to allow the high running speeds without operator fatigue