Inserts and Outserts

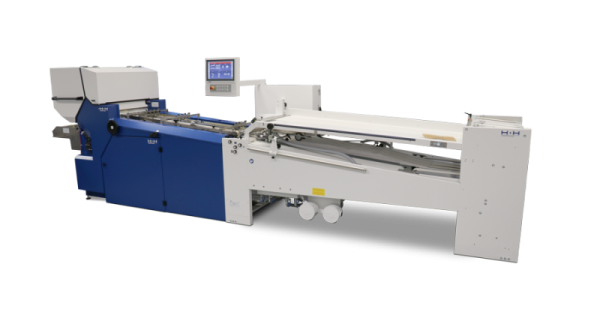

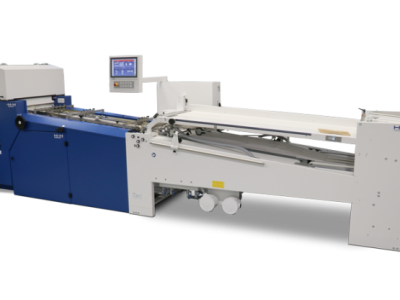

Insert and Outsert Production-M9 Folder

The M9 is designed for the production of inserts, outserts, PI’s and miniature literature in the pharmaceutical, electronics, cosmetics, food, agricultural and similar industries. It is available as a manual version, or as a highly automated time saving, labor reducing system. The M9 is the first production machine capable of automatically setting the buckle plate and fold roller settings for up to 24 plates in this market. The long list of quality check and uptime enhancements provide a remarkable reduction in set-up times and overall machine productivity. The M9 folder with M1 advanced controls is the miniature folding machine platform for the future. Final fold size requirements can range down to 1.12” x 1.12”. Outsert type products usually use an adhesive closure method, or a tab closure method. MBO America offers pharma insert and outsert production systems to produce products ranging from 12 to 350 panels. The M9, along with modular knives and pressing units, come together to produce these highly specialized systems.

Highlights:

- Machine control M1 Advanced including touchscreen (MIS compatible)

- Saving of repeating jobs

- Extra long register table with additional belt guide on the right for perfect sheet alignment

- Ejection before the folding unit to avoid double sheets

- 10, 12, 16, 20 or 24 buckle plates

- Optional automated buckle plate and fold roller settings

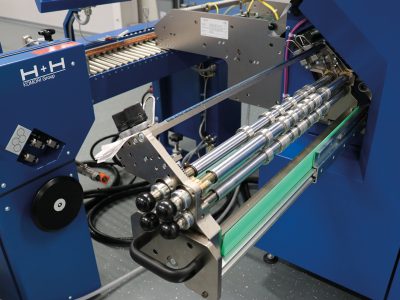

- Ergonomic slitter shaft cassette with two slitter shaft pairs

- Conveyor with integrated ejection module for misfolded sheets

- Expandable with individual modules

Extensions for the M9:

The M9 is suitable for both parallel and cross fold work. It can be optionally expanded. The components presented here are only examples of some of the many expansion options.

- PP600 belt press

The M9 has an integrated conveyor that permits multiple-up production. The inserts produced in multiple-up production can be pressed perfectly using the optional PP600 belt press. - Extension to the outsert line

A further option is the extension to the outsert line. Various cross fold designs and parallel knife folding units cover virtually every folding option. - Closing of products

Products can be closed either using a cold glue system or a labeler. - SmartPACK100

The SmartPACK100 is used to check the folded outserts against quality criteria with a camera system. Imperfect products are ejected into a lockable container. This practically avoids products being intermixed. The automatic filling of the trays with the folded pharmaceutical inserts completes the perfect outsert production line with consistent productivity. - XP-D250

As an option for the SmartPACK100, the M9 can also be operated with the manual XP-D250 delivery.

Features:

- Automation

The buckle plates and fold rollers of the H+H M9 can be set automatically as an optional feature. This is carried out via the M1 Advanced machine control using an intuitive touchscreen. The automation plays an important role in reducing set-up times. - Sheet alignment

The sheet infeed is carried out by the R80 continuous feeder with Vacubelt system or by the F80 pile feeder. The feeder has a 1.8 m (70”) long alignment table with additional transport belt on the right-hand side for faultless sheet transport. - Waste sheet ejection

The integrated sheet ejection unit ejects any double sheets before the folding unit. An optional camera system on the register table can also be integrated.