177 Vertical Stacking Delivery

Overview:

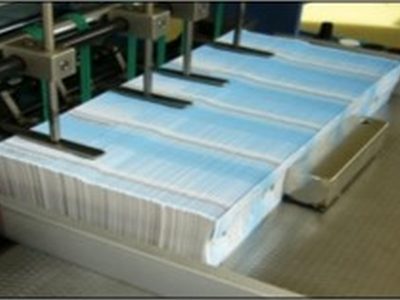

The 177.1 delivery from HH is the standard for most miniature folding systems. This unit turns the product vertical as it stacks to form an easy to handle stream that has a greatly reduced build rate. A kicking assembly can help mark batch counts so the operator can be more efficient. The 177.1 is available in two versions, a mobile unit (used by most) and a hang-on unit. Both units come with independent self-control, which allows it to be used in a wider range of configurations including lines with older machines or machines from other suppliers. The mobile version has an easy height adjustment to fit to different machine exits for a wide range of applications. Designed by specialty finishing experts, Herzog+Heymann, the 177 Vertical Stacking delivery is a robust unit capable of 24/7 operation in high volume facilities.

Highlights:

- Spine up stacking for easy visual quality check

- Builds in a log style stream on a flat table using side guides

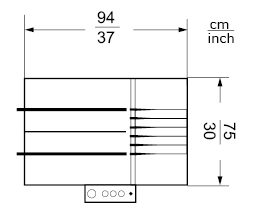

- Working width: 45 cm (17.7”)

- Capable of producing 1 up or 2 up streams

- Mobile frame design with casters and foot lock

- Height adjustable by electrically controlled lift cylinder from 630 mm – 930 mm (24.8” – 36.6”)

- Photocell and kicker included to separate batch counts for operator

- Independent self-control for easy integration with many other units

- Round belt infeed system for added control at the infeed

- Outfeed table extension for extended operator time between lifts

- MBO 24-pin electrical connection for integration to modular components (Note: this configuration is designed for integration to other modular components, plug for self-drive operation is not provided)

- Three phase drive motor for long term, robust service