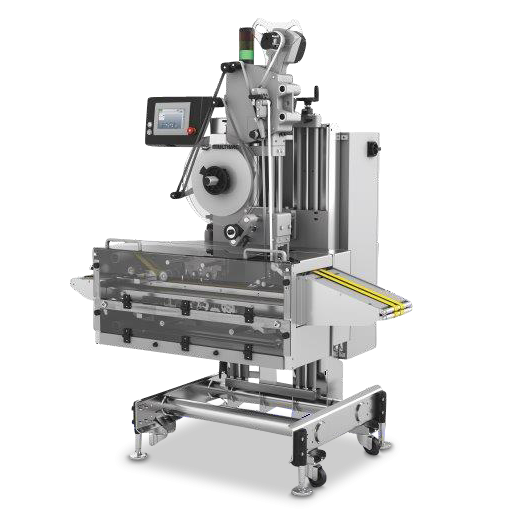

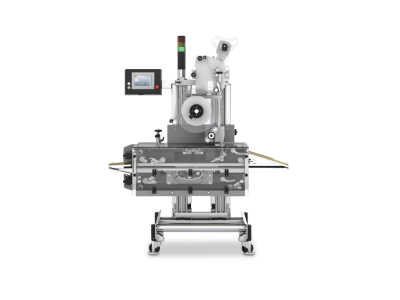

L350 Labeler/Tabber

Overview:

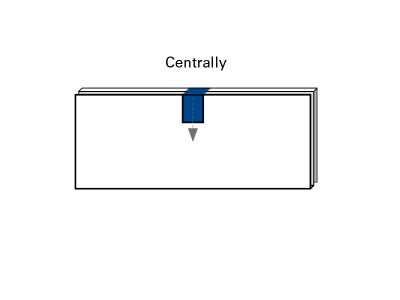

The L 350 applies a single label/tab, on one side, to seal the open edge of a folded product, for example a pack leaflet or outsert. The unit is modular and height adjustable to place easily behind any folder or upstream process. An extended discharge area ensures that the products are safely transferred to downstream line components. The product thickness can be easily set between 0.5 and 20 mm covering a wide range of products. Sealing labels from a roll with a silicone release liner of 15, 20 or 25 mm wide, are dispensed onto the rear edge of the product and then applied around it by means of an air blowing nozzle and a pressing applicator. Servo drives ensure the maximum output and precision are achieved, and interchangeable dispensing edges and format plates assure the L 350 can be converted quickly and conveniently to many label widths or paper sizes.

Features and Benefits:

- Central height adjustment for easy connection to any folding machine

- Extended discharge area for easy transfer to downstream components

- High productivity for up to 12,000 products/hour

- Simple setting for different product thicknesses

- Quick conversion to alternative paper formats and label sizes

- Convenient controls using the HMI 2.0 user interface

- Designed to use of low-maintenance components

- Large range of options and additional functions available