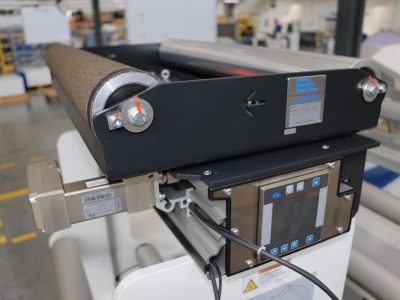

UW 23 Unwinder (23.0")

The UW 23 unwinder from MBO is a constant tension feeding unit for rolls up to 23.0″ wide and 52″ in diameter. In web finishing, it all starts with great delivery of the web to the system. This means that tension and guiding must be accurate and consistent. The UW 23 has a dancer tension control system with a core driven roll shaft for accurate web tension control. The unwinder has an integral electric paper lift and splice table as well as a de-curling device. The solid design with strong steel frames and robust roll drive gives these high-end modules maximum operation capability, reliability of the production process, as well as a long operating life even in a 24/7 operation.

Features & Benefits:

- For use as an offline/near-line solution

- Up to 52 inch roll diameter for greater press or finishing line uptime

- Large diameter idler rollers to minimize web-curling and tension disturbance

- Quick release shaft chucks to eliminate tooling and shorten roll change time

- Precise unwind control even with full size, heavy rolls at maximum speed

- Integrated splice table with edge guide and clamps helps reduce setup times

- Electric paper lift reduces worker injury and speeds up the roll change process

- Pneumatic, active dancer rollers on a swing arm create a buffer between the finishing line and the unwind for the best tension control

- Independent web tension control

- Integral web guide for precise web delivery to the finishing line

- Decurling device removes web curl for better paper handling to increase quality in printing and finishing

Optional Considerations:

- Splice Sensor to prevent mill splices from going through downstream processes

- 3” or 5” diameter core shaft

- Right angle layout possible using WTS air flotation angle bar

- Inline configuration with OEM printing press is possible

Image Gallery

Technical Specifications

UW 23 Unwinder on 20" digital web finishing line