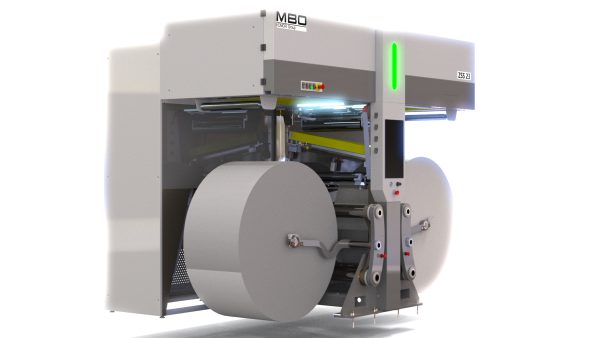

Zero Speed Automatic Splicer ZSS 23

The MBO ZSS 23 Horizontal Zero Speed Splicer further reduces makeready and increases up time of finishing lines. Using butt splice technology, the ZSS 23 automatically attaches a full roll to the end of an expiring roll so the press or finishing line can operate non-stop. For longer runs, rolls can be spliced into the line to keep it running, reducing the normal downtime of a manual unwinder by 10-15 minutes per roll. For example, lines finishing a 100# text weight roll (about 30,000 feet) nearly every hour at 500 fpm, gain about 20%-25% uptime using the ZSS 23. Makeready time for stock changes is greatly reduced because the roll can be prepared in advance while the current job is ending, then spliced in immediately. The shaftless design eliminates heavy lifting of expired rolls and coreshafts.

Features

- Roll core support system

- Motorized roll side-lay positioning

- High performance core accelerator

- Direct roll loading from floor for both roll positions

- Bi-directional unwind capability

- Servo controlled nested festoon

- Integrated web break detector

- Constant tension infeed tension control with accuracy +/- 1%

- Color HMI with for all operator interface

- Butt splicing and in-register