Greeting Cards

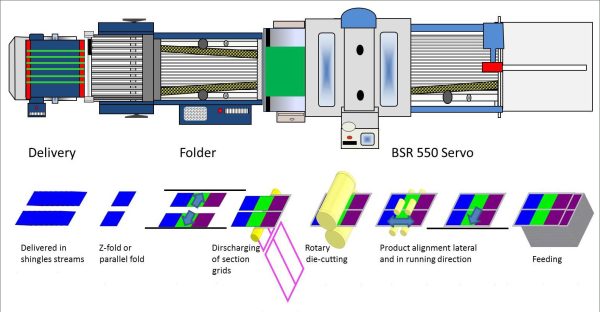

Using the BSR Rotary Diecutter

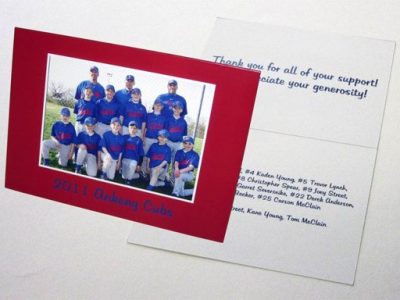

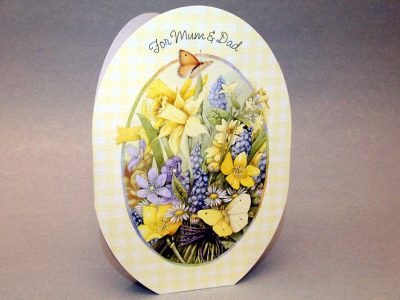

The BSR Rotary Diecutter works well for all popular size greeting cards. The cards can be contour shaped or square corners and even have internal window cut outs. Multiple up layouts on the sheet are die-cut with clean, nick-free edges, then delivered in a shingled stream to the delivery table in the case of the BSR Basic Model and can be integrated into a folder in the case of the BSR550 Servo Full Version. The scrap matrix is stripped away, along with any internal hole slugs for things like hanger holes or windows. Speeds up to 8,000 sheets per hour are possible on the BSR Basic model and 12,000 sheets per hour on the full version. Labor is reduced to a minimum because there are not additional steps to remove the scrap or to grind off nicks. Machine uptime is at a high level due to the short makeready times for hanging rotary die plates and setting up the programmable stripping unit. Because of the short makeready and high speed capability, the BSR can fit into the fast paced digital print world or be comfortable in the high volume offset world.

Features and Benefits:

- Single step process reducing labor and shorter turn times

- Nick free edges for the highest product quality

- Short makeready for more machine uptime

- Repeatable die changes for recurring jobs

- B2 format to allow digital and offset sheet work

- Contour cuts on the die eliminate corner machines and contour machines

- Scoring on the die eliminates a second step offline

- Window capability extends the capability to other markets

This Solution Generally Consists of…

- BSR 550 Servo Rotary Die Cutter

- 091 Series Mailing Table

- Various Deliveries

- Or the economical version is the BSR Basic Rotary Diecutter