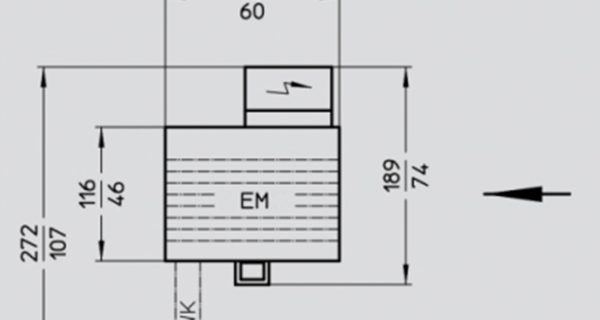

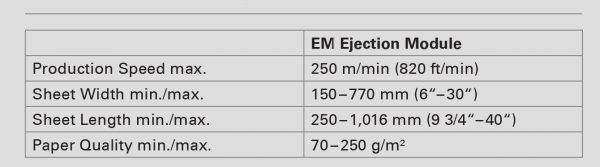

EM Ejection Module

Overview:

The EM Module is made to scan the product stream in a rollfed inkjet finishing line, then identify and eject “bad impressions” without interrupting production. These types of sheets are commonly printed by modern continuous feed inkjet presses for a host of reasons including misprints, jet-outs, missing finishing marks, calibration sheets and white waste, all needing to be removed from the finishing stream. By eliminating these sheets via the EM Ejection Module, the finishing line keeps running without pause greatly increasing efficiency and accuracy of their final product.