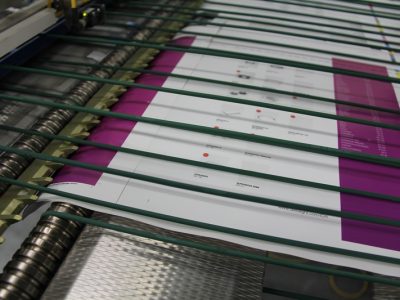

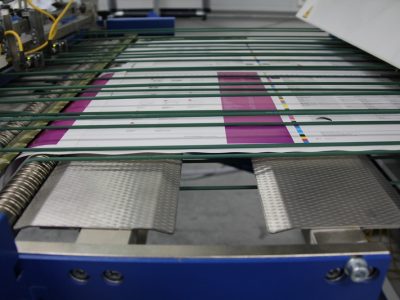

T800.1 Buckle Folder

The T800.1 is MBO’s premium buckle folding machine for full size B1 and smaller sheet sizes. With a blazing maximum speed, 230 meter/minute (9,055 inches/minute), and wide range of fold pattern capabilities, it is well suited to the North American commercial print market. Common 25″ x 38″ sheets can be processed up to 13,755 sheets/hour, and smaller sheets even faster! Even with conservative estimates, this represents a substantial increase in production rates over nearly any earlier vintage folding machine. MBO’s latest M1 controls platform uses a simple graphical interface with intuitive menu choices and complete integration for operation ease. Connectivity to the internet provides a way for MBO to gain remote access for service or software upgrades. Easier processes, user friendly controls and automated functions, get jobs on and off the machine faster, translating to more uptime and maximum productivity. Even in today’s fast turn, short run market, the T800.1 is allowing today’s printer to think in terms of replacing vintage machines at a ratio of up to 2:1 or more while still reducing labor.

Highlights:

- High production rates that can replace older vintage folders at 2:1 or more

- Easy to learn M1 controls platform ensures a great labor pool for the future

- Configuration flexibility allowing perfect fit for nearly any application

- Robust design for low maintenance costs and high machine uptime

- Exclusive low maintenance and noise-free belt drive

- Exclusive high speed cone rollers for optimal sheet transfer rate

Standard Features and Benefits:

- 6/4/4 buckle plates configuration for optimum flexibility in the commercial print market

- M1 advanced control system with easy to learn HMI and menu system

- Manual or Automated buckle plates and fold roller settings to fit the application

- R 80 Continuous feeder or FP 80 Palletized feeder to fit the application

- MBO’s Slitter Shaft Cassette design for fast tooling changes in unit 1

- Pre-slitter shaft prior to the buckle plates in unit 1 for additional perf and score capability

- Virotec fold rollers in unit 1 for best fold quality and non-marking properties

- Transfer belt units after folding sections to add control to the product between the units

- Interface to multiple deliveries and other MBO modules to customize the application for the best ROI

- Remote access software, RAS, system for connectivity with MBO service

Optional Features and Benefits:

- Datamanager 4.0 for presets and folding performance data collection and analysis

- Extension to 6 buckle plates in unit II

- Gatefold plate for added fold offering to your customers

- Multiple fold roller surfaces for best performance with specific stocks and print

- Transfer tables with ejection capability for bad product detection

- Alternating deflector for increased folding speed on wide products

- Two lane guide systems for increased productivity when 2 up folding

- Slitter shaft tooling assembly kits for presetting scores, perfs and slits and fast makeready

- MBO Sheet Return Device, RFE, to move the delivery of the folder back towards the feeder for less labor

- Many delivery choices, including automated palletizing with MBO’s CoboStack

- Sslitter shaft cassette for fast tooling changes and fast make-ready in second or third units