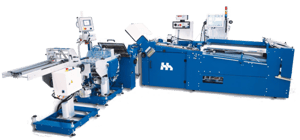

T50 BUCKLE FOLDER

90 PANEL AND UNDER

MBO America offers unique systems to produce folded literature with 12 to 90 panels, using a variety of folding modules. The lines are generally equipped with 8-12 buckle plates in the first section, a variety of modules creating the remaining fold pattern and closed with glue or a label. Systems can be combined with options for camera inspection, quality checks and more. MBO is a leader with the use of a label to close the folded product, minimizing the puffy end product commonly made when glued. Furthermore, label closing preserves 4 more panels for information and the tighter closure leads to more products in the tray for better feeding results at the packaging line. Whether you need traditional glue closure or upgraded label closure, MBO America provides the small panel count market with efficient systems.

The Herzog+Heymann KL 90 Panel Outsert Line is the production solution for producing glued outserts efficiently, cost-effectively and therefore profitably. The concept is based on the expertise from decades of experience in the field of minimum-size folds and provides the optimal entry into outsert production with a price/performance ratio unique on the market.

Depending on the job structure and job volume, the outsert line can be equipped with a continuous feeder or a flat pile feeder. To maintain reliable processing and continuous production – even with very thin papers – ultrasound double sheet control is installed in both feeder types as standard.

Optional mix-up inspection using a camera system and optional glue application control in the knife folding unit also increase production reliability.

To produce even flatter end products, the optional water-scoring system for fold preparation can be integrated into the first folding unit. This gives a further productivity increase as more products can be packed into the cartons and trays, which has a noticeably positive effect on the subsequent production stages.

FEATURES

- Minimum fold length of 18 mm (0.71”)

- Glue closure or label closure at the final fold

- Use of knife or pressing units depending upon panel count and thickness of product

- Choice of web fed, pile fed or continuous fed configurations giving you the right solution for nearly all applications

- Modular design and unique configurations with labelers, knife units, gluers, turners, deliveries and more, can be combined for customized solutions

TECHNICAL SPECIFICATIONS