T50 BUCKLE FOLDER

BOOKLETS AND LABELS

The Herzog+Heymann KL 90 Panel Outsert Line is the production solution for producing glued outserts efficiently, cost-effectively and therefore profitably. The concept is based on the expertise from decades of experience in the field of minimum-size folds and provides the optimal entry into outsert production with a price/performance ratio unique on the market.

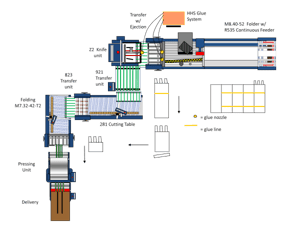

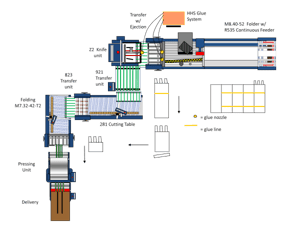

Depending on the job structure and job volume, the outsert line can be equipped with a continuous feeder or a flat pile feeder. To maintain reliable processing and continuous production – even with very thin papers – ultrasound double sheet control is installed in both feeder types as standard.

Optional mix-up inspection using a camera system and optional glue application control in the knife folding unit also increase production reliability.

To produce even flatter end products, the optional water-scoring system for fold preparation can be integrated into the first folding unit. This gives a further productivity increase as more products can be packed into the cartons and trays, which has a noticeably positive effect on the subsequent production stages.

BOOKLET SYSTEM FEATURES AND BENEFITS

- Diecut tabs and/or running perf lines for each fold made prior to the folding process

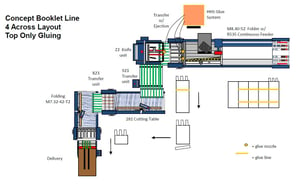

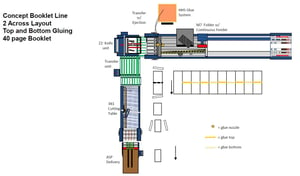

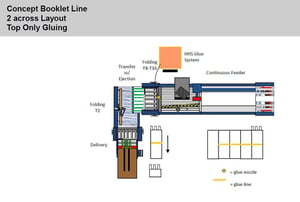

- Continuous feeder or pile feeder available to match production environment

- Glue System (1 line for 2 wide / 2 lines for 4 wide) with glue detection prior to first fold

- Gluing from the top to reduce misting and spray issues

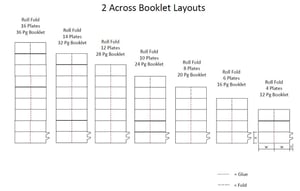

- Up to 16 plate folder is common to roll fold glued booklets

- Transfer units and rejection gates after process steps remove glue problems, wrong sheets, bad folds, etc.

- Machine heights are kept at higher, operator friendly levels to reduce injury

- Spine down delivery to preserve tabs

- Higher machine throughput compared to legacy machine systems

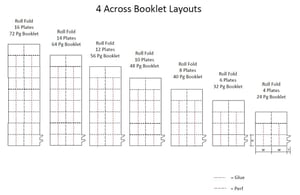

- 2 wide or 4 wide panel layouts possible for increased page counts

TECHNICAL SPECIFICATIONS